A Pilot Study of using Fire Risk Investigation in 3D (FRI3D) Software for Performing Fire Analysis of Plant Modifications.

The software Fire Risk Investigation in 3D (FRI3D) was developed under the US DOE Light Water Reactor Sustainability program. An important goal of this project was to simplify and automate parts of the detailed fire analysis specified in NUREG 6850 which will reduce the costs and maintainability of fire modeling. Over the past years, this project developed methods and an easy to use interface to combine existing industry tools in a way that eliminates many of the manual tasks previously needed for fire probabilistic risk analysis PRA thereby minimizing potential errors. FRI3D couples existing plant data, 3D modeling, fire simulation codes like Consolidated Model of Fire and Smoke Transport(CFAST), Fire Dynamics Simulator(FDS) , and PRA to automate the creation of fire scenarios, using accepted and least conservative methods given the data available.

Initially industry data and test cases were used to evaluate industry potential FRI3D verify FRI3D capabilities and validate the results. The next step prior to larger industry use and deployment is to demonstrate it use with pilot projects and industry scenarios. This paper gives a concise description of FRI3D and key features for industry use along with the results working with an industry plant and expert fire PRA consultants on using FRI3D for a plant modification.

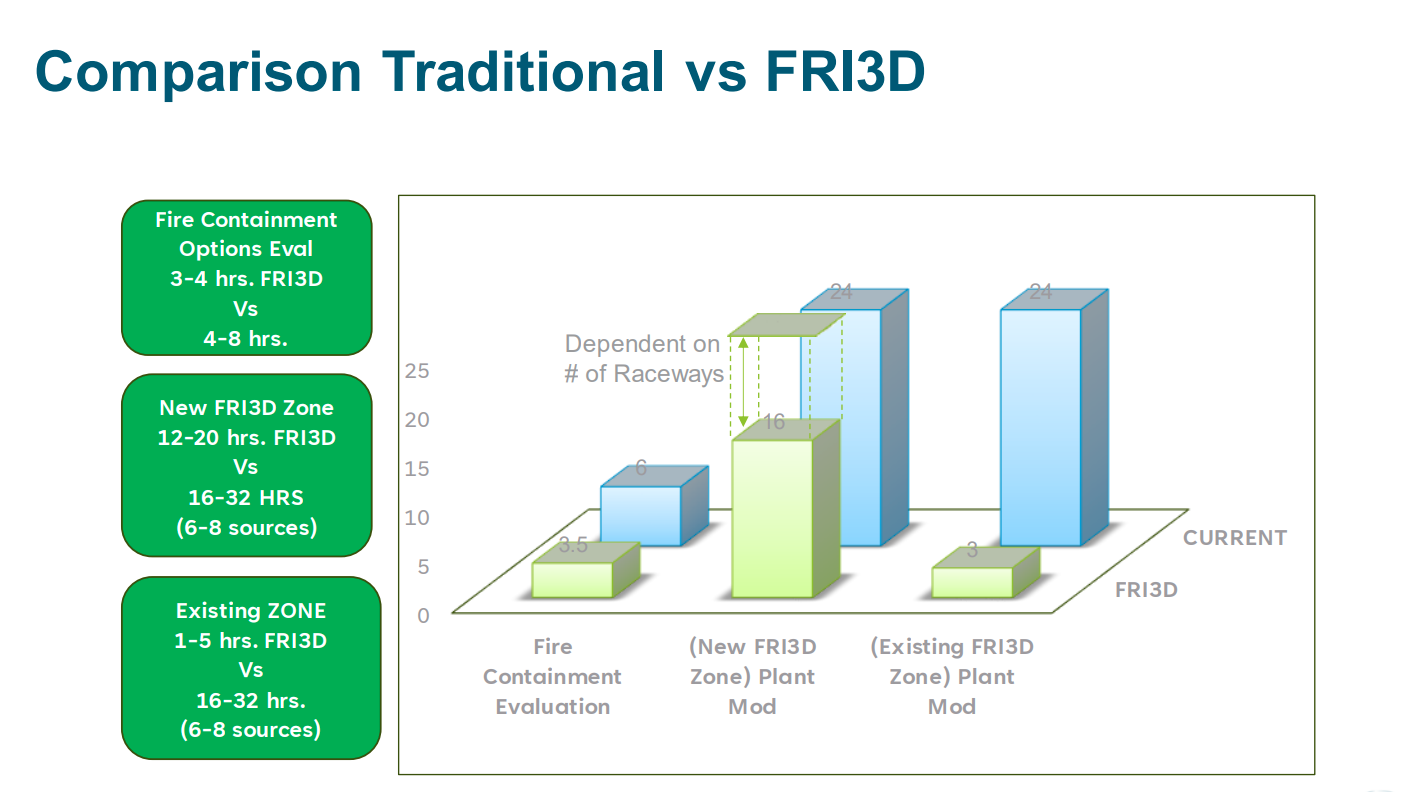

FRI3D Time Savings