FDS Introduction

FDS is a powerful fire simulator which was developed at the National Institute of Standards and Technology (NIST). FDS simulates fire scenarios using computational fluid dynamics (CFD) optimized for low-speed, thermally-driven flow. This approach is very flexible and can be applied to fires ranging from stove-tops to oil storage tanks. It can also model situations that do not include a fire, such as ventilation in buildings.

FDS models can predict smoke, temperature, carbon monoxide, and other substances during fires. The results of these simulations are used to ensure the safety of buildings before construction, evaluate safety options of existing buildings, reconstruct fires for post-accident investigation, and assist in firefighter training.

FDS Fire Specfication in FRI3D#

FDS can specify fires a couple of different ways

The first is to specify an heat release rate on a surface; this is the same as prescribing a well defined burner.

The other is to specify thermophysical properties of fuel materials and to let them pyrolyze. In this case the burning rate of the fuel depends on the net heat feedback to the surface.

In FRI3D we specify a Heat Release Rate under Fire Materials for a fire specification. In FDS this corresponds to the mass rate of fuel introduced.

FDS output results in a HRRPUA (Heat Release Rate Per Unit Area) directive. This is actually the simplest and the most reliable approach.

In FRI3D, since the Fire is described based on an object which is put on the scene, its dimensions are used to calculate the bounding area to normalize the area to send that information as normalized HRRPUA.

FDS needs atleast a single REAC line to be used with the mixture fraction model. The stoichometric coeffients specified in the interface for Fire Material is used for the REAC line in FDS.

FDS can either take energy per unit mass of Oxygen that is reactive for pyrolysis or heat of combustion specification. Since FRI3D uses Heat release rates as inputs Heat of Combustion is specified in the Fire Material user interface.

FDS Heat of Combustion in FRI3D#

This heat of combustion specification in FRI3D refers to the gas phase combustion specification. For FDS If the stoichiometry of the burning material differs from the global reaction, the heat of combustion is used to ensure that an equivalent amount of fuel is injected into the flow domain from the burning object.

FDS Stoichiometry in FRI3D#

The burning process releases heat and smoke.

Whereas there can be many types of combustibles in an FDS fire simulation, one only gaseous fuel can be simulated by FDS. In general, you should set the chemistry of the modeled burning gaseous fuel to coincide with the actual predominant burning gaseous fuel.

The stoichiometry of the predominant gas phase combustion reaction is prescribed in the the user interface specification of the fire material. Since Cl is not used by FDS, this is ignored.

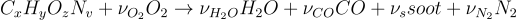

FDS implements the following chemical reaction as the combustion reaction. The various stoichiometric coefficients are converted into their respective volume fractions to be output as FDS directives.

The volume fractions of the chemical constituents which represent the combustion reaction are calculated and specified as directives. This is based on the fire specification entered by the user, details of which is explained in the section on FRI3D Sources.

However the following is an example of FDS directives as output by FRI3D for fire sources.

&SPEC ID = 'PE/PVC', FORMULA = 'C2H3.5Cl0.5' / &SPEC ID = 'OXYGEN', LUMPED_COMPONENT_ONLY = .TRUE. / &SPEC ID = 'NITROGEN', LUMPED_COMPONENT_ONLY = .TRUE. / &SPEC ID = 'HYDROGEN CHLORIDE', LUMPED_COMPONENT_ONLY = .TRUE. / &SPEC ID = 'WATER VAPOR', LUMPED_COMPONENT_ONLY = .TRUE. / &SPEC ID = 'CARBON MONOXIDE', LUMPED_COMPONENT_ONLY = .TRUE. / &SPEC ID = 'CARBON DIOXIDE', LUMPED_COMPONENT_ONLY = .TRUE. / &SPEC ID = 'SOOT', LUMPED_COMPONENT_ONLY = .TRUE.,FORMULA='C1' /&SPEC ID='AIR', BACKGROUND=.TRUE., SPEC_ID(1)='OXYGEN', VOLUME_FRACTION(1)=0.21, SPEC_ID(2)='NITROGEN', VOLUME_FRACTION(2)=0.79 /

&SPEC ID='PRODUCTS',SPEC_ID(1)='HYDROGEN CHLORIDE', VOLUME_FRACTION(1)=0.5,

SPEC_ID(2)='WATER VAPOR', VOLUME_FRACTION(2)=1.5,

SPEC_ID(3)='CARBON MONOXIDE', VOLUME_FRACTION(3)=0.2376,

SPEC_ID(4)='CARBON DIOXIDE', VOLUME_FRACTION(4)=1.2496,

SPEC_ID(5)='SOOT', VOLUME_FRACTION(5)=0.5128,

SPEC_ID(6)='NITROGEN', VOLUME_FRACTION(6)=7.9692 /

&REAC ID='PE/PVC', HEAT_OF_COMBUSTION = 20900., SPEC_ID_NU='PE/PVC','AIR','PRODUCTS', NU=-1,-10.0876,1, RADIATIVE_FRACTION = 0.49 /

Secondary Fires#

The approach to model secondary fires in FDS differs from the approach used in CFAST. This difference is because FDS can simulate the spread of secondary fires while CFAST cannot. The following procedure steps were used to model secondary fires in FDS from FRI3D:

- Determine if there are cable raceways above the initial fire following the FLASHCAT geometry.

- If there are, sort the raceways according to their distance from the fire.

- Assign the fire spread rate to each raceway according to their cable type. The fire spreads laterally with a rate of 1.1 m/hour for thermoset cables and 3.2 m/hour for thermoplast cables. If there are multiple cable types in a raceway, use the most conservative (the fastest) fire spread rate.

This is automatically setup when a FRI3D Scene is setup and FDS is used for simulation.