What is FRI3D?

FRI3D is an integrated fire modeling and visualization system aimed to simulate fire scenarios and visualize these metrics quickly, with an easy to use interface designed to reduce effort needed for Fire Risk Modeling, cut operational and turnaround times and reduce user errors by automating many of the tasks.

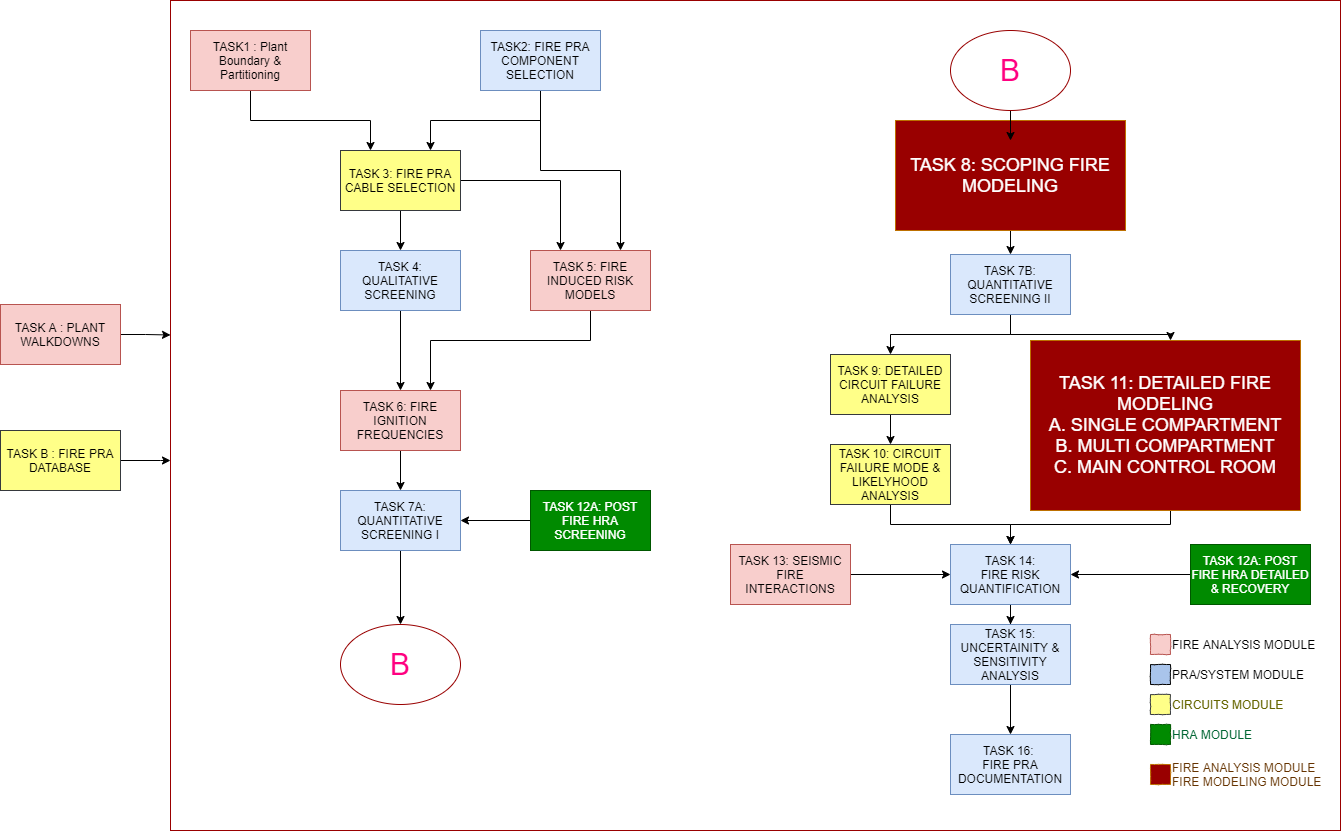

When creating a fire model, there are specific steps and methodologies that need to be taken into account. NUREG 6850 report from the the Nuclear Regulatory Commission (NRC) outlines the guidance on how to create an acceptable fire model and all of the elements to be considered for Nuclear Power Plants. There are ten steps that outline the general process for creating a fire PRA and describes where FRI3D can simplify or automate the process: The following flow chart illustrates the fire analysis as performed in the Nuclear Industry

FRI3D assists in the process of detailed fire modeling specifically.

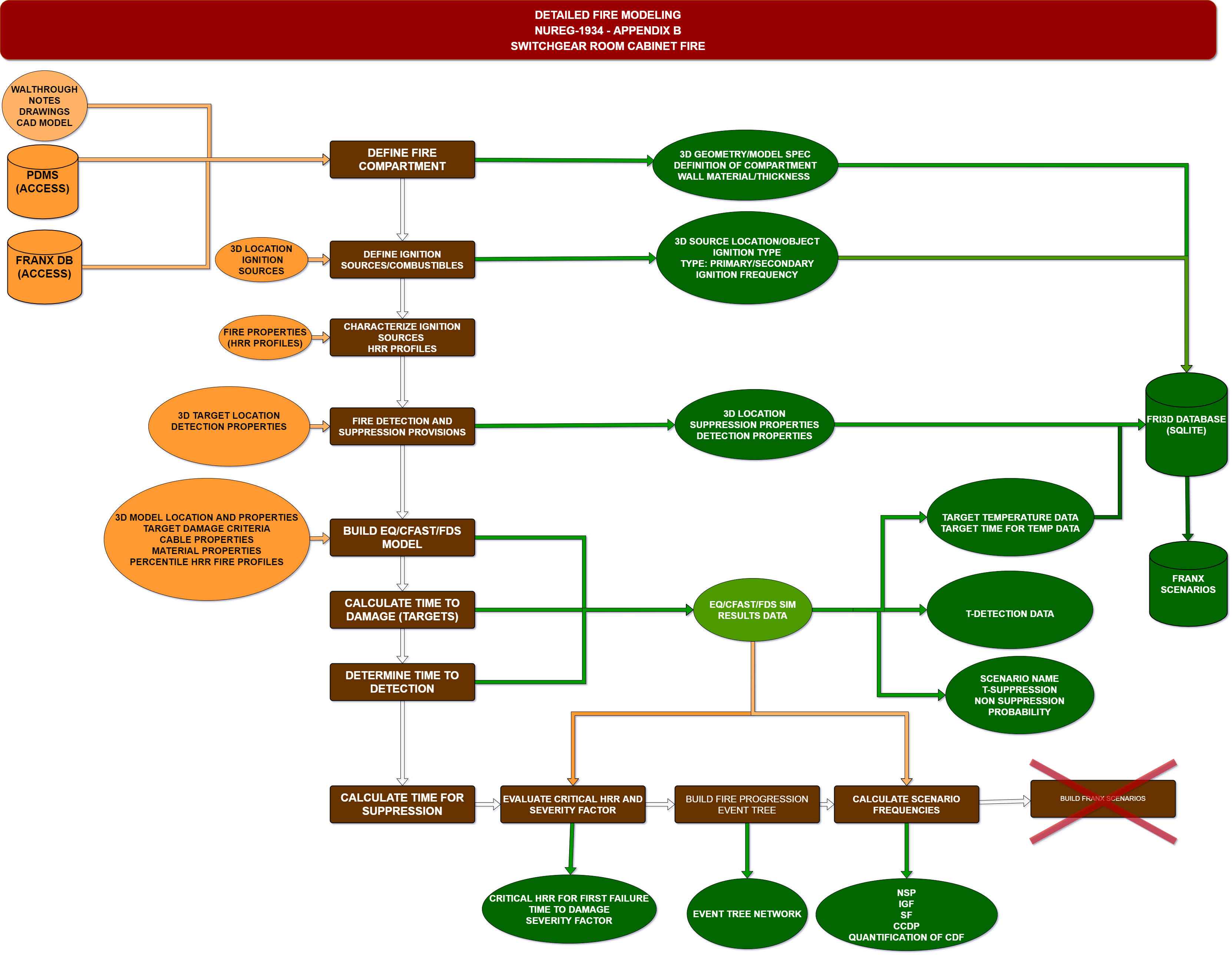

The detailed fire modeling workflow pipeline is illustrated by the following figure

FRI3D's solution uses two components, the FRI3D User Interface and the FRI3D backend processing system to perform advanced fire analysis for an entire system with or without exising databases or pre-existing fire models. FRI3D delivers highly optimial performance with little or no manual intervention in the various processes involving fire simulation and fire probablistic risk analysis.

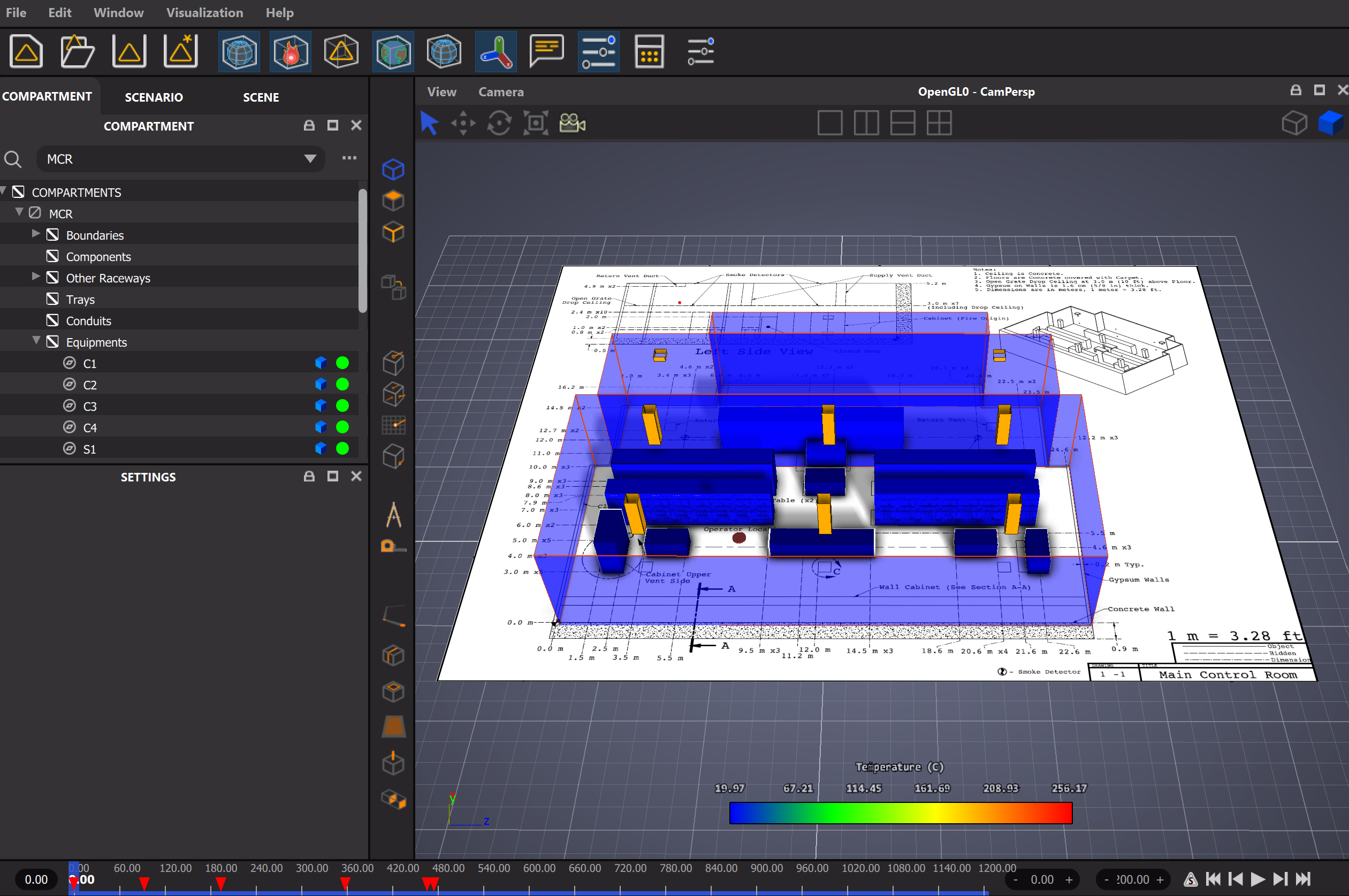

FRI3D UI

You can install FRI3D on most Windows distributions with Linux distributions planned (Ubuntu, Debian, CentOS, and more).

What you can do with FRI3D

FRI3D is designed to be both simple to use and flexible for fire modeling, visualization, and troubleshooting use case:

- Model: FRI3D's methodology and tools intended for engineers to perform their simulation tasks quickly allows them to model complex compartments in a fraction of the time.

- Simulate: FRI3D's interface to validated simulation codes like CFAST enables the user to quickly simulate a variety of scenarios in a fraction of the time.

- Visualize: FRI3D's advanced visualization tools enables users to quickly determine scenarios of interest.

- Troubleshoot: FRI3D's tools make it possible for an engineer to troubleshoot and fix issues related to the analysis in a fraction of the time of what was possible before.

- Store: FRI3D's efficient database engine efficiently stores the plant data, fire analysis results metrics in an easy to access relational database based on SQL.

What's next?

Learn more about why you should use FRI3D, or how FRI3D works with your existing databases and analysis.