Why use FRI3D?

The design goal of FRI3D is to integrate the key aspects of fire PRA modeling, namely the PRA logic model, spatial model, and fire simulation, into single easy-to-use platform. The software can import a plant’s existing FRANX fire PRA model and plant data bases such as Plant Data Model System (PDMS). FRI3D is currently coupled with Consolidated Fire and Smoke Transport (CFAST) for fire simulations and Computer Aided Fault Tree Analysis System (CAFTA) for risk analysis.

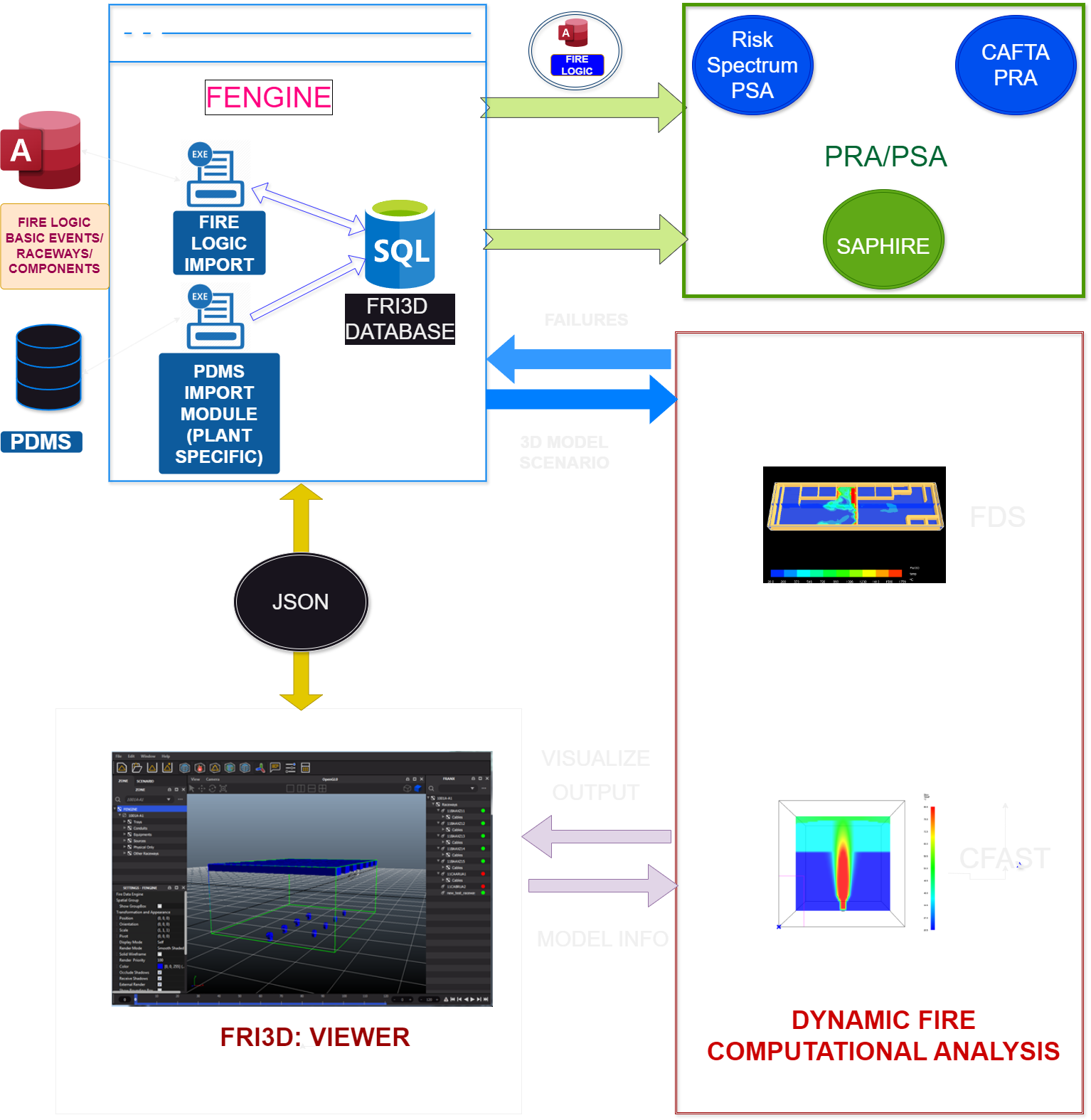

The process is illustrated by the following

Multiple Fire Scenario Capabilities

A typical approach for fire scenario selection is iterative. Analysts often start with a very conservative scenario selection and refine scenarios that contribute the most to the overallrisk. A very conservative scenario assumes a full room burnout—all the equipment and cables in the same fire zone as the source are failed due to fire with no credit taken for fire suppression. If the risk contribution from this overly conservative scenario is insignificant, then no refinement is needed. For fire zones where the initial overly conservative approach results in a fire risk that is too large, refinements are made where multiple fire scenarios are defined depending on fire severity. The components are placed in the fire scenarios, or bins, according to the fire with significant enough HRR to fail those components. Multiple fire scenarios can be defined; each scenario characterized by a specific Target Set, HRR, severity factors, and non-suppression probability.

Fire scenario definition is not a trivial task since it requires knowledge and experience from the fire engineer to identify which equipment in the zone can be damaged by a fire with certain HRR. This is where FRI3D becomes a valuable tool since it allows a quick simulation of multiple fire bins (i.e., fire scenarios). Each fire bin scenario run will demonstrate equipment that is failed or not failed due to the postulated fire. This quick (matter of minutes) exercise would allow the fire engineer to select the number of fire bins for a given fire zone; each bin associated with a set of equipment (i.e., Target Set) affected by each scenario.

Easy to setup 3D Modeling Capabilities

The user interface of FRI3D makes it quite easy to facilitate and speed up a fire model. This includes the capability to model a compartment and setup its equipments participating in the fire analysis. Users are able to create complex models and rooms with setup to be used to simulate in about a fraction of the time as is currently done.

Powerful and scalable

- Less % CPU utilization/ RAM, and minimal disk I/O to run a fire model quickly.

- Configurable granularity to run simulations for hours or for seconds.

Optimized for visualization & troubleshooting

- Visual anomaly detection with an integrated 3D visualization system and UI/UX that enables the user to determine issues quickly.

- On Screen Display and Color Coded Values to pinpoint correlated metrics, for visual inspection, and help you streamline your fire modeling workflow.

Comparison with other fire modeling solutions

FRI3D offers many benefits over the existing fire modeling landscape, whether they're expensive SaaS products or other open-source tools.

| FRI3D | Others (open-source and commercial) |

|---|---|

| Most processes are automated | A lot of manual entries are needed |

| Fast UI | UI may or may not be present |

| Relational Database to store models and info | Manual or non relational database |

| Plant Data in 3D with advanced visualizations | Plant data manual entries |

| Integrated CAD Model capabilities | CAD Modeling has to be done externally if needed |

| Integrated FLASHCAT method for cable failures | Need manual post processing runs to determine cable failures |

| Integrated Visualization, to help you understand the model | Not integrated visualizations |

| Easy setup to and get results quickly | Long process to setup the model |

| Easy troubleshooting due to visual cues and feedback | Difficult to troubleshoot |

| Visual Troubleshooting | Manual troubleshooting |

| Requires minimal training for fire modeling | Requires exhaustive training |

| Automated processes for reducing user errors | Many manual steps may be involved |

| Integrated CFAST and requires no model change for other fire codes | Each fire simulation code require a separate workflow |

| Integrated Scenario Visualization of fire scenarios with failures | Requires other codes and visualization tools |