HeatSoak Calculations

HEATSOAK Model

FRI3D employs two methodologies to estimate cable failure from the fire simulation results, namely heat-soak and THIEF methods. The heat-soak method is the simplest out of the two. It uses a lookup table for time-to-damage as a function of constant exposure. This method considers the cumulative effect of preheating that may occur at lower temperatures then the damage threshold temperatures. Heat soak calculates a variable called the damage integral based on the time-dependent reaction rate. Damage occurs when this damage integral is greater than or equal to 1. The damage integral formula is given by:

Where is the damage integral and is a time-dependent reaction rate, which is assumed as the inverse of the exposure duration as follows:

Where is the exposure temperature at time t, and is the time until damage for that temperature, Cable failure occurs when the damage integral reaches 1:

| Time (min) | Temperature (C) | Time-to-damage (from NUREG 6850) | Damage rate (min-1) | Damage integral |

|---|---|---|---|---|

| 0 | 210 | 30 | 0.033 | 0 |

| 1 | 320 | 5 | 0.2 | 0.12 |

| 2 | 350 | 3 | 0.33 | 0.38 |

| 3 | 320 | 5 | 0.2 | 0.65 |

| 4 | 320 | 5 | 0.2 | 0.85 |

| 5 | 320 | 5 | 0.2 | 1.05 (Failure) |

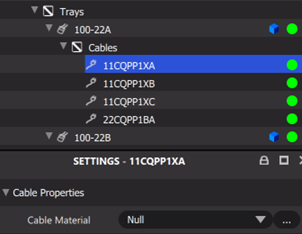

The main variable in determining the damage integral is the cable’s type, whether it is thermoset or thermoplastic. For that reason, FRI3D uses heat-soak method by default, by selecting the conservative setting when detailed data of the cable is not provided by the modeler in the FRI3D model. To use this method, simply add a “Cable” in FRI3D and leave the material properties at “Null” as shown in the figure below